Rock Impact mills, accessories and construction

frequently serve purposes in . They can be manufactured locally or as .

allow rock to be , facilitating the .

In ’s and ’s rural areas, such are being built on-site due to their effectiveness for immediate needs.

A limited number of parts—such as —are sourced externally or bought in , , or .

All locations where machine components can be acquired are meticulously recorded. Since rural towns lack metal supply stores, serve as sources for necessary parts.

- SYOGM Rock Impact Mill

SYOGM Rock Impact Mill refers to low-cost, highly efficient, crushing and grinding impact mill with capacity of 500 kg and even up to 900 kg per hour. Capacity depends of the operator's skills and speed of work. This type of rock impact mill can easily replace rudimentary and very expensive ball mills such as those used in East Africa, in Tanzania, Uganda or Kenya or neighboring countries. While local village miners need to dry their rocks, this rock impact mill will work with water and without drying. It may process dry rocks as well. The machine may be transported by 2 people from a car to operating site. Or it may be transported by one person and wheelbarrow. Thus it is very mobile. Recovery screen is 1 mm and may be adjusted. We know from practical testing and scientific journal that screen of 1.5 mm is good enough to achieve almost optimum recovery. Thus our screen of 1 mm is more than enough to provide optimum recovery for small scale miners in East Africa and in other countries. This is pass-through grinding machine. It means that it may be used for very quick gold discovery and field sampling.

SYOGM Rock Impact Mill refers to low-cost, highly efficient, crushing and grinding impact mill with capacity of 500 kg and even up to 900 kg per hour. Capacity depends of the operator's skills and speed of work. This type of rock impact mill can easily replace rudimentary and very expensive ball mills such as those used in East Africa, in Tanzania, Uganda or Kenya or neighboring countries. While local village miners need to dry their rocks, this rock impact mill will work with water and without drying. It may process dry rocks as well. The machine may be transported by 2 people from a car to operating site. Or it may be transported by one person and wheelbarrow. Thus it is very mobile. Recovery screen is 1 mm and may be adjusted. We know from practical testing and scientific journal that screen of 1.5 mm is good enough to achieve almost optimum recovery. Thus our screen of 1 mm is more than enough to provide optimum recovery for small scale miners in East Africa and in other countries. This is pass-through grinding machine. It means that it may be used for very quick gold discovery and field sampling. - Feeder for SYOGM Rock Impact Mill

This is feeder for the impact mill, shown from different side.

This is feeder for the impact mill, shown from different side. - SYOGM Rock Impact Mills And Classifier In The Workshop

One can see here our favorite, for decades experienced metal technician who is leading the workshop in construction of our mining equipment. The program Start Your Own Gold Mine is conducted in East Africa, in Rwanda, Uganda, Kenya and Tanzania, and provide our clients with full SYOGM™ Gold Recovery Plant with 10 tonnes capacity per hour.

One can see here our favorite, for decades experienced metal technician who is leading the workshop in construction of our mining equipment. The program Start Your Own Gold Mine is conducted in East Africa, in Rwanda, Uganda, Kenya and Tanzania, and provide our clients with full SYOGM™ Gold Recovery Plant with 10 tonnes capacity per hour. - Perforated metal screen used in SYOGM Rock Impact Mills

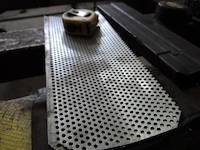

This type of perforated metal screen is used in impact mills with more or less opening sizes depending of the need.

This type of perforated metal screen is used in impact mills with more or less opening sizes depending of the need. - Feeders for impact mills

One may see the feeder mounted on one of the impact mills.

One may see the feeder mounted on one of the impact mills. - The production of SYOGM Rock Impact Mills in our workshop in Croatia

This picture shows the production of impact mills in our workshop in Croatia. Each such impact mill may handle 500 kg of rocks per hour and more than that.

This picture shows the production of impact mills in our workshop in Croatia. Each such impact mill may handle 500 kg of rocks per hour and more than that. - The construction of impact mills for rock milling

On this picture one can see some details of the construction of impact mills in our workshop in Croatia, Europe. Each such impact mill has capacity of minimum 500 kg per hour, and may mill the rocks down to the powder as small as 50 mesh and smaller.

On this picture one can see some details of the construction of impact mills in our workshop in Croatia, Europe. Each such impact mill has capacity of minimum 500 kg per hour, and may mill the rocks down to the powder as small as 50 mesh and smaller. - The impact mills during the manufacture time

These are the impact mills during the manufacture in our workshop in Croatia. Each impact mill may handle about 500 kg of material easy, or even more with better classification or setups. They are manufactured by company's financed blueprints and engineered designs, and by technician with decades of experience.

These are the impact mills during the manufacture in our workshop in Croatia. Each impact mill may handle about 500 kg of material easy, or even more with better classification or setups. They are manufactured by company's financed blueprints and engineered designs, and by technician with decades of experience. - This is the pulley as used on our impact mills

This is pulley made in the workshop in Novska, Croatia. It is used to run the impact chain flail rock mill.

This is pulley made in the workshop in Novska, Croatia. It is used to run the impact chain flail rock mill. - The drum for the impact mill

This is the drum and hardened chains shown on picture.

This is the drum and hardened chains shown on picture. - Our main workshop to produce gold mining equipment is in Croatia

This is our main workshop for 2018 for construction of gold mining equipment. It is located in Novska, Croatia. Mining equipment is transported by ship from Croatia to Tanzania or Uganda.

This is our main workshop for 2018 for construction of gold mining equipment. It is located in Novska, Croatia. Mining equipment is transported by ship from Croatia to Tanzania or Uganda. - Turner preparing the cover

This is turner machine that is used to prepare the covers for impact chain flail rock mills.

This is turner machine that is used to prepare the covers for impact chain flail rock mills. - The drum for SYOGM Rock Impact Mill

These drums are steel pipes cut in pieces to serve for construction of the SYOGM Rock Impact Mill.

These drums are steel pipes cut in pieces to serve for construction of the SYOGM Rock Impact Mill. - Plan for the foundation of the impact chain flail rock mill

This is the plan on how to make a foundation for the impact chain flail rock mill. The rock mills we are using in the last step of rock processing.

This is the plan on how to make a foundation for the impact chain flail rock mill. The rock mills we are using in the last step of rock processing. - The rock crusher or impact chain flail rock mill

This is the view from above on the impact chain flail rock mill.

This is the view from above on the impact chain flail rock mill. - Impact chain flail rock mill from behind

This is the impact chain flail rock mill from behind. It offers the opportunity to crush and mill up to 1000 lbs of rocks per hour.

This is the impact chain flail rock mill from behind. It offers the opportunity to crush and mill up to 1000 lbs of rocks per hour. - The screens of the impact chain flail mill

These are the screens as shown from inside of the impact chain flail rock mill.

These are the screens as shown from inside of the impact chain flail rock mill. - One of best crushers or rock mills also known as Beast

This is the rock mill or crusher, the impact chain flail mill for rocks and perfect for small scale mining. This type of crushers is able to process 1000 lbs per hour when properly fed, or half of it when fed more relaxed. It is good for an entry into the small scale mining and is used in the program Start Your Own Gold Mine.

This is the rock mill or crusher, the impact chain flail mill for rocks and perfect for small scale mining. This type of crushers is able to process 1000 lbs per hour when properly fed, or half of it when fed more relaxed. It is good for an entry into the small scale mining and is used in the program Start Your Own Gold Mine. - The heavy chains in hardware store in Busia

The heavy chains in hardware store in Busia may be used in the chain impact mill that may influence the gold recovery.

The heavy chains in hardware store in Busia may be used in the chain impact mill that may influence the gold recovery. - Possible source for a drum

Such gas bottle can be cut in pieces and 2 drums could be made out of the cylinder. Yet the metal wall is not as thick as we would like it. We do not know if it is worth trying for US $19.22 how much the scrap dealer asked us that day, or approximately 70,000 Ugs.

Such gas bottle can be cut in pieces and 2 drums could be made out of the cylinder. Yet the metal wall is not as thick as we would like it. We do not know if it is worth trying for US $19.22 how much the scrap dealer asked us that day, or approximately 70,000 Ugs. - Not a choice for this drum

This piece of metal scrap was used in some other historical machine. The idea was to convert it to the drum for our impact mill, yet it would not work as this metal is not good for welding purposes.

This piece of metal scrap was used in some other historical machine. The idea was to convert it to the drum for our impact mill, yet it would not work as this metal is not good for welding purposes. - Possible drums for the impact mill

This is a possible drum for the impact mill. We are reviewing scrap metal supplies as no other source of metal is available nearby. Local welders cannot bend the metal properly.

This is a possible drum for the impact mill. We are reviewing scrap metal supplies as no other source of metal is available nearby. Local welders cannot bend the metal properly.