- SYOGM Advance Wash Plant Design

- Related pages

SYOGM Advance Wash Plant Design

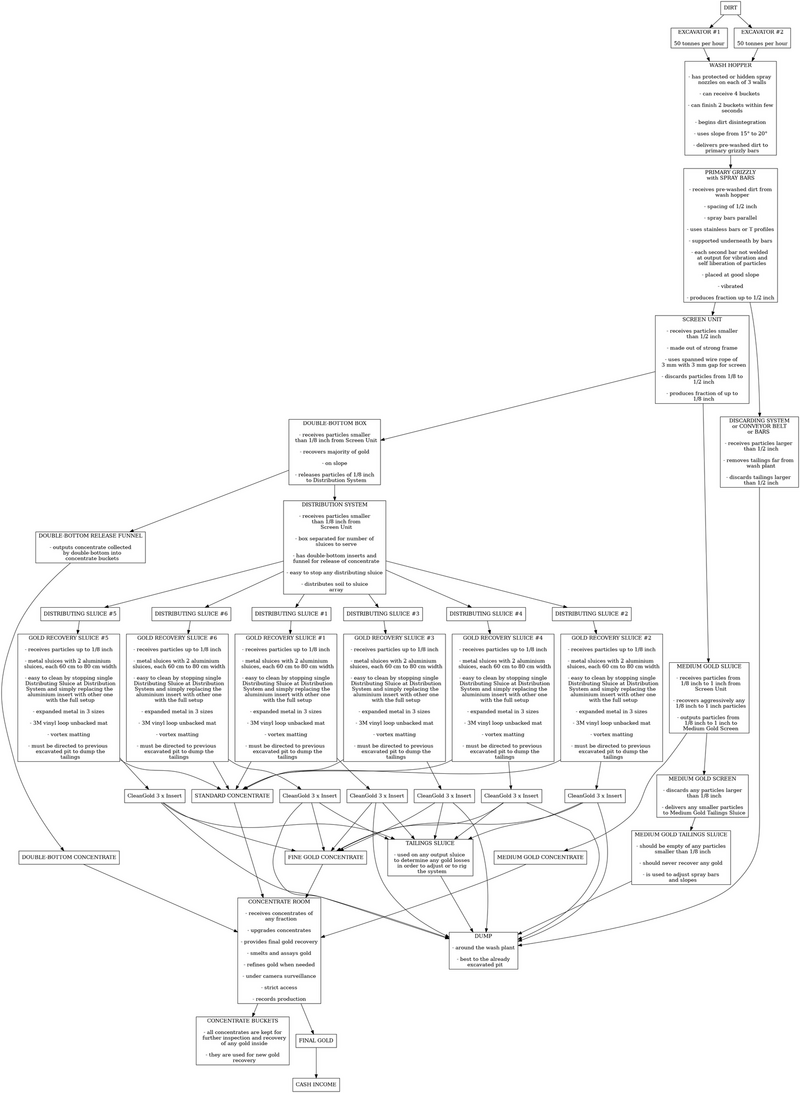

The SYOGM (Start Your Own Gold Mine) Advance is an that allows miners to efficiently and effectively extract gold particles from dirt. The wash plant design incorporates various components and processes to ensure optimal extraction and .

The is designed for .

At Start Your Own Gold Mine, we specialize in for any capacity, from 30 to 300 tonnes per hour and more. Our expertise extends to include , allowing miners to . Our incorporates state-of-the-art technology and components, ensuring efficient and effective extraction and recovery of gold. With our advanced system, while minimizing effort and resources. Whether you are a or , has the expertise and solutions to meet your gold extraction needs.

Components and Processes of the Gold Mining Wash Plant

Excavators

The is operated by which can process each about 50 tonnes of dirt per hour each. The effective operation and are essential for . It is crucial to adopt a systematic approach in order to maximize efficiency. Minimizing unnecessary movements, trucking, and excavations from one heap to another is of utmost importance. Every soil excavation should be directed straight to the wash plant in order to minimize expenses.

are particularly well-suited for due to their exceptional ability to efficiently remove large volumes of overburden and sediment while minimizing ground disturbance. These are capable of digging deep into riverbeds or to access that might be overlooked by smaller excavators. With their expansive reach and , can place material directly onto the wash plant, streamlining the process and enhancing productivity. Additionally, their size allows for the handling of significant amounts of material in a single pass, which not only reduces the number of necessary movements but also optimizes the overall workflow. This efficiency translates to lower operational costs and higher yields, making an invaluable asset in the quest for placer gold.

A can be efficiently loaded with dirt using both pipes and conveyor belts. In alluvial mining sites, where soil is dredged from rivers or ponds, the plant can be conveniently connected to pipes to direct the soil straight into it. This enables a seamless process of extracting gold, as the plant receives a continuous supply of material, ensuring a smooth and efficient workflow. Additionally, the use of facilitates the transportation of materials to and from the , further .

Wash Hopper

The is the first component that the dirt passes through. It features protected or hidden on each of its three walls, as well as additional on the frames above the wash hopper. The wash hopper can accommodate up to four buckets of dirt and disintegrates the soil while delivering pre-washed material to the primary . It has a slope that ranges from 15° to 20°. This slope is determined by the angle of repose under wet conditions and varies depending on the type of soil being mixed with water. It is crucial to emphasize the importance of spraying water in the wash hopper, as it serves as the initial entry point for soil into the system.

The is of paramount importance when designing and . We emphasize that thorough testing of the wash hopper must be an integral part of our contractual agreement with clients. It is essential for the design to incorporate a detachable mechanism, allowing the wash hopper to be easily removed from the main structure of the wash plant for maintenance and optimization purposes.

To enhance the , we advocate for the inclusion of on the primary wash hopper. This configuration aims to maximize the initial disintegration of soil and facilitate the liberation of gold as the material enters the hopper. By optimizing the interaction between the water and soil, we ensure a more effective and efficient washing process, ultimately leading to .

Primary Grizzly Bars

The receive the pre-washed dirt from the wash hopper. These bars have a spacing of ½ inch and are supported underneath by bars. The bars are not welded at the output every second bar, allowing for vibration and self-liberation of particles. The bars are placed at a good slope and vibrate to produce a fraction up to ½ inch.

Prior to determining the optimal slope angle for the gold wash plant, it is crucial to assess the under wet conditions. This evaluation is essential, as it directly impacts the stability and efficiency of the operation. We emphasize that may still hold significant economic value, even after crushing and milling. Therefore, we strongly recommend that include guidance on incorporating additional machinery to from any discarded rock.

The is to , specifically those exceeding ½ inch in size. These oversized materials should be thoroughly washed to ensure that no or adheres to their surfaces, thereby enhancing the overall .

Screen Units

are received by the . The screen unit is made up of a strong frame and uses spanned with a 3 mm gap for the screen. It discards particles from 3/8" to ½ inch and produces a fraction of up to 3/8 inch.

In addition to the primary screen unit, additional screen units may be employed to further refine the . By using multiple screening stages, we can achieve a more uniform group of particle sizes, which significantly aids in the subsequent gold recovery process when using sluices. This and during the , minimizing the risk of fine gold being lost among larger particles. As a result, the not only enhance the but also increase the overall productivity of the operation.

False-Bottom Box

from the screen unit first drop into the . The false-bottom box recovers the majority of gold and releases particles of 3/8 inch to the distribution system as overflow.

This is a primary . The box does not need to be frequently cleaned as the gold is collected in the gold collection funnel under the wash plant.

and water spray from the machine ensure that the majority of gold drops into the false bottom and gets stuck there.

Gold Collection Funnel

The is strategically located beneath the false-bottom box, serving as the component of the wash plant. Its design facilitates the gradual accumulation of gold particles into the funnel. When operated correctly, the funnel can be utilized throughout the gold washing process without the risk of losing any gold.

Gold is transferred into a stainless steel pipe equipped with two valves. The upper valve is locked first, allowing the lower valve to release the gold into the collecting tube. To ensure that all particles are effectively extracted, the can be submerged in water, which helps dislodge any remaining gold. A specialized brush can be employed to thoroughly clean the pipe without losing any gold particles.

Once the cleaning process is complete, the bottom valve is locked, and the upper valve is opened to resume operation. This method guarantees maximum efficiency in gold recovery while minimizing potential losses.

Valves should be fitted with a padlock to guarantee the security of the gold.

Distribution System

The receives from the screen unit. It is separated into multiple boxes to serve a number of sluices. The distribution system may also have false-bottom inserts and a funnel for the release of concentrate. It is easy to stop any distributing sluice and distributes soil to the sluice array.

It is crucial to emphasize that the distribution system should begin at a sufficient height to enable the slurry to flow freely towards the gold recovery sluices. Additionally, it should be positioned on both sides of the to ensure and a systematic approach.

Gold Recovery Sluices

For or more, we recommend utilizing , each containing , resulting in a positioned on both the left and right sides of the gold wash plant. This same configuration is also recommended for , which are, in fact, the most efficient option available.

Each sluice is designed to handle in size. The consist of two aluminum sections, each measuring , a dimension that has proven to be user-friendly. is a straightforward process; simply stop a single distributing sluice within the distribution system to replace the matting or entire sluice inserts. The sluices incorporate expanded metal in three different sizes, along with a 3M unbacked and . The are channeled back into the previously.

are interconnected and can be easily transported; they can also be used individually in exploration mode. This allows for the deployment of six distinct sluice sets across six different locations, each requiring a minimum of three operators and capable of processing between six to ten tonnes per hour.

It’s important to note that it’s the width of the sluice that effectively recovers gold, rather than the length, which is a misconception often perpetuated by other gold wash plants. Due to transportation constraints, many plants utilize . However, longer sluices, combined with , leading to significant losses that can outweigh the overall value of the wash plant.

Medium Gold Sluice

The receives particles from 3/8 inch to 1 inch from the screen unit. It aggressively recovers any particles within this range and outputs them to the medium gold screen.

This sluice set is designed to following the primary grizzly screens. It is essential to thoroughly , as this setup primarily targets larger gold particles, and the sluices are configured differently.

If, after a comprehensive examination, no larger gold nuggets are detected, it is possible to exclude this sluice box from the system; however, we do not recommend doing so.

Medium Screen

The discards any particles larger than 3/8 inch and delivers any smaller particles to the medium gold size sluice.

Tailings Sluice

The is used on any output sluice to determine any gold losses and adjust or rig the system accordingly. It should be empty of any particles smaller than 3/8 inch and should never recover any gold. The is also used to adjust spray bars and slopes.

Water pump or water supply

The , serving as the lifeblood of the entire operation. Its primary function is to provide a consistent and adequate supply of water, which is essential for the effective separation of gold from other materials in the ore. This ensures that the wash plant operates efficiently, allowing for the proper washing and processing of gravel, sand, and other materials that may contain precious minerals. Without a reliable water pump, the plant would struggle to maintain optimal flow rates, leading to decreased productivity and potentially lower gold recovery rates. Additionally, the pump must be capable of handling various water conditions, including sediment-laden sources, which can impact its performance. As such, the quality and reliability of the water pump are pivotal for the overall success of gold mining operations, emphasizing its role as an indispensable element in the quest for extracting valuable resources from the earth.

The water pipes are designed to allow for adjustments in water flow, enabling an increase or decrease as needed. They also make it possible to attach separate hoses and utilize additional sluices in the wash plant.

Furthermore, in geographical regions where the land configuration allows for the implementation of an elevated water source, we strongly advocate for the strategic investment in piping systems to exploit this natural advantage. Utilizing gravity-fed water systems not only reduces the long-term operational costs associated with energy consumption required for water pumps but also provides a more sustainable and environmentally friendly solution for water distribution. By channeling water directly from a higher elevation, we can significantly enhance the efficiency of water delivery, ensuring a consistent and reliable supply for agricultural, domestic, or industrial needs. Moreover, this approach can mitigate potential mechanical failures and maintenance issues commonly associated with pump systems, leading to a more resilient infrastructure. Overall, embracing the use of gravity in water transport not only optimizes resource use but also fosters greater water security and sustainability in the communities that rely on it.

Concentrate Room

The receives concentrates of any fraction and upgrades them. It provides final gold recovery, smelts and assays gold, and when needed. The concentrate room is under , has strict access control, and records production.

We take pride in the fact that our is a product of our own manufacturing. It is designed with two distinct rooms to optimize functionality and efficiency. This mobile unit is easy to transport via truck, allowing for quick relocation as needed, or it can be constructed using available structures already present on your site.

Safety is our top priority, especially when it comes to the concentrate room, which is specifically designed to protect against theft. It is equipped with advanced security features, including and strict access control measures. Only authorized personnel are allowed entry, and all activities are meticulously recorded to ensure accountability.

Within this secure environment, the concentrate room efficiently receives concentrates from any fraction and upgrades them through various processes. It facilitates , , , and, when necessary, the , ensuring that the entire operation meets the highest standards of safety and quality.

Cleangold Inserts

The are used in the to collect the . Each .

The represents the most advanced gravitation-based available today, specifically engineered to while . This innovative system is capable of , which are often . Given that the , the plays an indispensable role in any effective gold wash plant. With each sluice equipped with three inserts, the system ensures optimal capture of concentrates, ultimately enhancing the efficiency and .

Concentrate Buckets

All concentrates are stored in for further inspection and the recovery of any . The bucket system can be considered the most crucial element of gold recovery, as it facilitates organization and and the various stages the concentrates undergo during the . Any startup company should obtain at least before operation. The is responsible for managing these materials, with the buckets providing an efficient means of handling them.

Final Gold and Cash Income

Once , it must be for purity in the . Essential tools for this process include , , , , , , , , , , , , , , and . All of these components are integral to the .

The final or further processing. It represents the cash income for the miners.

How the SYOGM Advance Wash Plant Works

The follows a series of processes to extract gold from dirt efficiently. Here is a step-by-step guide on how it works:

collect dirt and deposit it into the .

The disintegrates the dirt and delivers to the .

The vibrate to dislodge and .

The pre-washed dirt is then passed through the , which discards particles from 3/8 to ½ inch and produces a .

Particles smaller than 3/8 inch are collected in the , where they are recovered, and again released to the .

The separates the particles smaller than 3/8 inch into .

The receive the particles and use expanded metal, , and to .

The are directed to the previous to discard any remaining materials.

The aggressively recovers to 1 inch and outputs them to the medium gold screen.

The discards particles larger than 3/8 inch and delivers the smaller particles to the medium gold tailings sluice.

The is used to adjust and slopes and to determine .

The are collected in the , where they are upgraded and undergo further processing if necessary.

The is stored for sale or further processing, representing the for the miners.

for further inspection and recovery of any gold inside.

The design incorporates various components and processes to optimize the extraction and recovery of gold from dirt. It ensures for miners in their own gold mines.

Technical School of Banja Luka

The Technical School of Banja Luka, , holds a special place in my memories. It was there, in the basement, where we engaged in . The amphitheater became our hub for fun and , while the challenges we faced with peers and professors taught us . Our journeys to and the technical drawings and we mastered shaped our growth. Though the hard work was daunting at times, it ultimately contributed to the creation of the , a testament to the foundation we built at this school.

Related pages

- Get Ready for Gold Rush: Essential Mining Equipment for Start Your Own Mine

Start Your Own Gold Mine is a leading manufacturer and supplier of top-notch fine gold recovery equipment and expert guidance for small and medium-scale gold mining startups, ready to unlock the gold rush and full-scale mining potential.

Start Your Own Gold Mine is a leading manufacturer and supplier of top-notch fine gold recovery equipment and expert guidance for small and medium-scale gold mining startups, ready to unlock the gold rush and full-scale mining potential. - SYOGM Rock Impact Mill

SYOGM Rock Impact Mill refers to low-cost, highly efficient, crushing and grinding impact mill with capacity of 500 kg and even up to 900 kg per hour. Capacity depends of the operator's skills and speed of work. This type of rock impact mill can easily replace rudimentary and very expensive ball mills such as those used in East Africa, in Tanzania, Uganda or Kenya or neighboring countries. While local village miners need to dry their rocks, this rock impact mill will work with water and without drying. It may process dry rocks as well. The machine may be transported by 2 people from a car to operating site. Or it may be transported by one person and wheelbarrow. Thus it is very mobile. Recovery screen is 1 mm and may be adjusted. We know from practical testing and scientific journal that screen of 1.5 mm is good enough to achieve almost optimum recovery. Thus our screen of 1 mm is more than enough to provide optimum recovery for small scale miners in East Africa and in other countries. This is pass-through grinding machine. It means that it may be used for very quick gold discovery and field sampling.

SYOGM Rock Impact Mill refers to low-cost, highly efficient, crushing and grinding impact mill with capacity of 500 kg and even up to 900 kg per hour. Capacity depends of the operator's skills and speed of work. This type of rock impact mill can easily replace rudimentary and very expensive ball mills such as those used in East Africa, in Tanzania, Uganda or Kenya or neighboring countries. While local village miners need to dry their rocks, this rock impact mill will work with water and without drying. It may process dry rocks as well. The machine may be transported by 2 people from a car to operating site. Or it may be transported by one person and wheelbarrow. Thus it is very mobile. Recovery screen is 1 mm and may be adjusted. We know from practical testing and scientific journal that screen of 1.5 mm is good enough to achieve almost optimum recovery. Thus our screen of 1 mm is more than enough to provide optimum recovery for small scale miners in East Africa and in other countries. This is pass-through grinding machine. It means that it may be used for very quick gold discovery and field sampling. - Terms and Conditions for Gold Mining Equipment Manufacturing by Start Your Own Gold Mine

Start Your Own Gold Mine offers comprehensive terms and conditions governing the manufacture, sale, and use of specialized gold mining equipment.

Start Your Own Gold Mine offers comprehensive terms and conditions governing the manufacture, sale, and use of specialized gold mining equipment. - Strategic Provisioning of Equipment to Village Miners in Exchange for Gold Benefits (Relationship Management)

This web page talks about a way for dealers and buyers to work together that is good for both sides. The dealers or buyers give miners in villages the equipment they need for mining gold. This helps the miners mine gold more efficiently. In return, the dealers and buyers get some of the profits from the gold-bearing rocks, or they get a good percentage of any precious metals that are found. They also get priority when buying these valuable resources and get discounts on future transactions.