- Practical Quantitative Gold Prospecting Methods: Moving from Guesswork to Measured Data

- The Misunderstood Role of Metal Detectors

- Gold Panning: The Prospector's First Quantitative Tool

- Systematic Bulk Sampling with SYOGM Recovery Systems

- Professional Feasibility: The SYOGM Advanced Wash Plant

- Subsurface Quantitative Methods

- Other Major Quantitative Methods

- Call to Action: Upgrade Your Resource Status

Practical Quantitative Gold Prospecting Methods: Moving from Guesswork to Measured Data

For the modern prospector or mining company, confirming the presence of gold is only the first step. The real value lies in accurately determining the quantity of gold—its grade and distribution—to make informed decisions about a property’s potential. This guide outlines practical methods for quantitative gold assessment, from simple panning to advanced professional techniques.

The Misunderstood Role of Metal Detectors

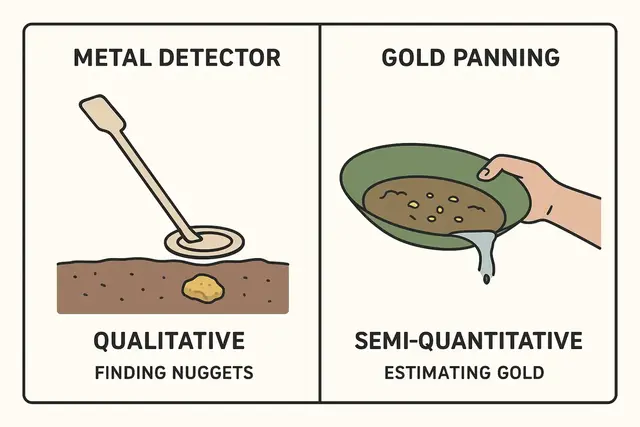

It is crucial to understand what tools are and are not quantitative.

- Purpose: A metal detector is an excellent qualitative prospecting tool. Its primary function is to locate visible or near-surface gold nuggets.

- Limitation: It does not provide a quantitative measure of gold content. Finding a handful of nuggets confirms gold is present but reveals nothing about the overall grade, the abundance of fine gold, or the total gold potential of the area.

- Use Case: Ideal for collecting large, individual specimens but is ineffective for estimating ore grade and should not be relied upon for resource calculation.

Gold Panning: The Prospector’s First Quantitative Tool

Often seen as a simple activity,gold panning can be transformed into a powerful semi-quantitative method with careful technique.

- The Method: By taking a representative sample of soil, sediment, or crushed rock from a known volume (e.g., a shovel scoop from a defined depth), you can process it thoroughly and count the recovered gold.

- The Outcome - The SYOGM Gold Classification: The results are categorized by particle size, providing a granular understanding of the deposit’s character:

- Extremely Fine Gold (EFG): 1-10 µm (flour gold)

- Very Fine Gold (VFG): 10-100 µm

- Moderately Fine Gold (MFG): 100 µm to 1 mm

- Medium Gold (MG): 1 mm to 5 mm

- Coarse Gold (CG): 5-10 mm

- The Grade Estimate: By recording the number of “colors” or specks per size category per unit volume of material processed, you can extrapolate a rough grade estimate (e.g., grams per cubic yard or tonne). This data is invaluable for deciding if an area warrants further, larger-scale testing.

Systematic Bulk Sampling with SYOGM Recovery Systems

For a truly accurate assessment, panning must be scaled up. This is where systematic bulk sampling comes in, using equipment designed for maximum recovery.

- Excavation: Pits or trenches are excavated in measurable dimensions (e.g., 6m x 8m) down to bedrock. The total volume of material is precisely recorded.

- Processing: All material is run through a SYOGM Fine Gold Recovery Sluice. These sluices are engineered to capture 99% of liberated gold, from Extremely Fine Gold (EFG) to Coarse Gold (CG), making them a quantitative tool. Discarded rocks can be further verified by crushing them in a SYOGM Rock Impact Mill to liberate any contained gold.

- Concentration and Analysis: The concentrates from the sluice are upgraded, and then by using classification sorted, refined by panning, and advanced methods like the Cleangold® sluice system to isolate the gold.

- Calculation: The total weight of gold recovered is compared to the total tonnage of material processed (using a calculated specific density). This provides a highly accurate direct grade calculation for that specific pit. Repeating this process across a property builds a robust dataset to understand the average grade and gold distribution.

Professional Feasibility: The SYOGM Advanced Wash Plant

For rapid, large-scale feasibility determination, a mobile wash plant is the ultimate solution.

- Method: A SYOGM Advance Gold Wash Plant, fed by an excavator, can process high volumes of material quickly. It integrates the same high-recovery principles as the smaller sluices but on an industrial scale.

- Benefit: This is the fastest way to process hundreds of cubic yards of material for grade determination. It requires significant investment and logistics (excavator, water pumps, transport) but provides definitive data faster than any other surface method.

Subsurface Quantitative Methods

Surface gold often indicates deeper deposits. Quantifying these requires specialized techniques.

- Ground-based High-Resolution Proton Magnetometer Survey: This is the critical first step for looking underground. It maps variations in the magnetic field caused by mineralized zones and geological structures (like iron-rich gold-hosting formations). It identifies precise targets for drilling, eliminating guesswork.

- Diamond Core Drilling: The global standard for subsurface quantification. A diamond-tipped drill retrieves a continuous cylindrical core sample from depths of hundreds of meters. This provides:

- Accurate depth and thickness of mineralized zones.

- Geological context (rock types, structures).

- Uncontaminated samples for precise assay and grade calculation. This data is essential for classifying resources under international standards (Inferred, Indicated, Measured).

- Shaft Sinking and Trenching: While providing excellent visual and bulk samples, sinking a shaft or driving an adit is extremely expensive and time-consuming. In our management experience, a combination of magnetometer surveys followed by targeted diamond drilling has consistently proven more cost-effective and informative for initial resource definition.

Other Major Quantitative Methods

Beyond the core methods above, other techniques include:

- Reverse Circulation (RC) Drilling: Another drilling method that uses percussion to bring rock chips to the surface. Faster and cheaper than core drilling but provides less geological detail.

- Soil and Geochemical Sampling: Systematic collection of soil samples analyzed for trace elements pathfinder elements associated with gold (e.g., Arsenic, Antimony). Used to identify anomalous areas for further testing.

- Geophysical Surveys (beyond magnetometry): Techniques like Induced Polarization (IP) or resistivity can help map sulfide deposits often associated with gold.

Call to Action: Upgrade Your Resource Status

Do you have a property with inferred potential? To advance from an Inferred resource to an Indicated or Measured resource—thereby significantly increasing its value and bankability—you need robust, quantitative data.

SYOGM Gold Exploration specializes in turning prospecting finds into quantified deposits. From systematic bulk sampling with our high-recovery sluices to professional diamond drilling management, we provide the data and expertise to prove your property’s worth.

Contact SYOGM Gold Exploration today. Let us help you transform your potential into proven resources.