Uganda

- Exploring the Economic Potential of Gold Mining in Mubende District and Kassanda, Uganda

* Captured Region Text Buffer name: *RCD TEMPORARY BUFFER* Buffer file: /home/data1/protected/tmp/2024-01-08-20:56:10-RCD TEMPORARY BUFFER.txt Time captured: 2024-01-09-11:42:28 - February 26th 2020, Transport of gold mining equipment over the river

- February 26th 2020, The view on the valley nearby the Bwindi Impenetrable Forest

- February 26th 2020, Very slippery road on the way to the gold mining site

- February 26th 2020, We had to somehow conquer the muddy slippery road

- February 26th 2020, Muddy soil on the road is making difficulties for our truck

- February 26th 2020, Difficulties short before the arrival to the mining site

- February 26th 2020, The road to the Bwindi Impenetrable Forest

There are many lodges for gorilla safari on the road to the Bwindi Impenetrable Forest.

There are many lodges for gorilla safari on the road to the Bwindi Impenetrable Forest. - February 26th 2020, Hills in Kisoro district, Uganda

- February 26th 2020, Arrival to mining site

The travel was long, about 500 kilometers to the mining site.

The travel was long, about 500 kilometers to the mining site. - February 26th 2020, Preparing the cabin for life and business

- February 26th 2020, Apprentice in the program Start Your Own Gold Mine

Work at the cabin.

Work at the cabin. - February 26th 2020, Apprentice in the program Start Your Own Gold Mine

The apprentice from Nigeria is coping very well with the orientation in the camp area.

The apprentice from Nigeria is coping very well with the orientation in the camp area. - February 26th 2020, The cabin on the mining site

One can see the cabin on the mining site, used for accommodation and storage. Shelves are used to stow more equipment in a nice manner.

One can see the cabin on the mining site, used for accommodation and storage. Shelves are used to stow more equipment in a nice manner. - February 26th 2020, Transport of grizzly bars over the timber bridge

Workers transporting grizzly bars over the river.

Workers transporting grizzly bars over the river. - February 26th 2020, supervisor Gaetano on mining site

Gaetano is a highly experienced and proficient mining site supervisor who possesses a diverse range of skills in gold, diamonds, and jewellery production. With extensive knowledge and expertise in the mining industry, Gaetano demonstrates exceptional leadership and organizational abilities, ensuring smooth operations at mining sites under his supervision. His proficiency in gold mining techniques, diamond evaluation, and jewellery production processes enables him to effectively oversee all aspects of these operations, from extraction and processing to the final creation of exquisite jewellery pieces. Gaetano's comprehensive skill set, combined with his dedication and passion for the industry, make him an invaluable asset to any mining project or jewellery production endeavor.

Gaetano is a highly experienced and proficient mining site supervisor who possesses a diverse range of skills in gold, diamonds, and jewellery production. With extensive knowledge and expertise in the mining industry, Gaetano demonstrates exceptional leadership and organizational abilities, ensuring smooth operations at mining sites under his supervision. His proficiency in gold mining techniques, diamond evaluation, and jewellery production processes enables him to effectively oversee all aspects of these operations, from extraction and processing to the final creation of exquisite jewellery pieces. Gaetano's comprehensive skill set, combined with his dedication and passion for the industry, make him an invaluable asset to any mining project or jewellery production endeavor. - Apprentice and client from Italy in the program Start Your Own Gold Mine

Our clients who participate on ground are apprentices in the program Start Your Own Gold Mine, they learn so many things. Representatives of clients on ground are also apprentices including close executives.

Our clients who participate on ground are apprentices in the program Start Your Own Gold Mine, they learn so many things. Representatives of clients on ground are also apprentices including close executives. - February 26th 2020, supervisor Gaetano before the final move to the mining site

It requires guts for doing what we are doing. Mine site supervisor Gaetano is seemingly enjoying the time before the final transfer of equipment to the mining site.

It requires guts for doing what we are doing. Mine site supervisor Gaetano is seemingly enjoying the time before the final transfer of equipment to the mining site. - February 26th 2020, equipment transport over the timber bridge

You may observe the timber bridge over the river Rohezanyinda. Our

people have transported all heavy equipment pieces without problem

over the very risky timber bridge.

You may observe the timber bridge over the river Rohezanyinda. Our

people have transported all heavy equipment pieces without problem

over the very risky timber bridge. - The Elephant Bee Hive Project in Katojo, Rubuguri, district of Kisoro, Uganda

The Elephant Bee Hive Project was the idea to place the beehives as a

natural and live fence to deter elephants not to exit the Bwindi

Impenetrable Forest. This way, people's crops could be saved. However,

the idea is not practical, as many beehives were abandoned first by

their bees, and second by their maintainers, the project is not

functional, and requires skilled people to work. We have made our own

Elephant Defense Project and have informed people that they could

plant chilli pepper around the crops to deter elephants, further, we

informed rangers of the Uganda Wild Life Authority that they could

bringing elephants' dung from other places of the forest to deter them

to exit the forest in the night. The implementation alone requires

funding and investments. We can provide only the advice.

The Elephant Bee Hive Project was the idea to place the beehives as a

natural and live fence to deter elephants not to exit the Bwindi

Impenetrable Forest. This way, people's crops could be saved. However,

the idea is not practical, as many beehives were abandoned first by

their bees, and second by their maintainers, the project is not

functional, and requires skilled people to work. We have made our own

Elephant Defense Project and have informed people that they could

plant chilli pepper around the crops to deter elephants, further, we

informed rangers of the Uganda Wild Life Authority that they could

bringing elephants' dung from other places of the forest to deter them

to exit the forest in the night. The implementation alone requires

funding and investments. We can provide only the advice. - The day of travel to mining site in Kisoro, Uganda

On this day we travelled to the new mining site, that is the area of Rubuguri in the district of Kisoro in Uganda. The suspension was in the air due to the road conditions and safety. We did arrive safe and well.

On this day we travelled to the new mining site, that is the area of Rubuguri in the district of Kisoro in Uganda. The suspension was in the air due to the road conditions and safety. We did arrive safe and well. - Jackfruit, jack tree or fene, locally fenesi fruit in Entebbe, Uganda, April 12th 2017

This is jackfruit or jack tree or fenne, locally named fenesi, in Entebbe, Uganda. Delicious fruit that everybody likes.

This is jackfruit or jack tree or fenne, locally named fenesi, in Entebbe, Uganda. Delicious fruit that everybody likes. - The trucks for sale in Entebbe, Uganda, April 12th 2017

These trucks were for sale in Entebbe, Uganda, in 2017, discovered during the VMTRADE market research.

These trucks were for sale in Entebbe, Uganda, in 2017, discovered during the VMTRADE market research. - Uganda Wildlife Education Centre Pointer, April 12th 2017

This was the Uganda Wildelife Education Center pointer begin of 2017. later in time they reworked it.

This was the Uganda Wildelife Education Center pointer begin of 2017. later in time they reworked it. - Beautiful fountaine at Imperial Mall in Entebbe, Uganda, April 12th 2017

This is beautiful fountain by Imperial Mall in Entebbe, Uganda.

This is beautiful fountain by Imperial Mall in Entebbe, Uganda. - Eatable flower in Entebbe, Uganda, April 12th 2017

This is eatable flower in Entebbe, Uganda.

This is eatable flower in Entebbe, Uganda. - Beautiful hair like tree flower in Entebbe, Uganda, April 12th 2017

This is beautiful hair-like flower on the tree in Entebbe, Uganda. If

one comes from Europe where we cannot see this type of flowers, we may

think that it comes from other planet.

This is beautiful hair-like flower on the tree in Entebbe, Uganda. If

one comes from Europe where we cannot see this type of flowers, we may

think that it comes from other planet. - Kampala Taxi Park with huge number of public taxis as of April 10th 2017

- Kampala Taxi Park as of April 10th 2017

## April 10th 2017

This is Kampala Taxi Park.

## April 10th 2017

This is Kampala Taxi Park.

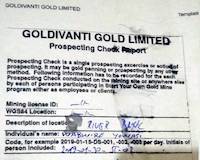

- Prospecting Check Report Example from Busia, Uganda

This is Prospecting Check Report near the area of Busia, Uganda. Every gold panning check is reported on the paper. That is how we collect the knowledge into the database.

This is Prospecting Check Report near the area of Busia, Uganda. Every gold panning check is reported on the paper. That is how we collect the knowledge into the database. - Gold particles in the gold pan, from river Okame, Busia, Uganda

These are gold particles found on the beach of river Okame, near Busia, Uganda, as compared to the known coin size.

These are gold particles found on the beach of river Okame, near Busia, Uganda, as compared to the known coin size. - Children swimming on the river Okame, near Busia, Uganda

Children are swimming in the river Okame, Busia, Uganda. This river is polluted by mercury from various spills of soil contaminated with it by mining operations. Uganda, as of 2019, still does not have any system or legal enforcements to contain the mercury.

Children are swimming in the river Okame, Busia, Uganda. This river is polluted by mercury from various spills of soil contaminated with it by mining operations. Uganda, as of 2019, still does not have any system or legal enforcements to contain the mercury. - One gold particle found in river Okame, Busia, Uganda

The one fine gold particle was found in river Okame, Busia, Uganda. The top soil does not contain much gold.

The one fine gold particle was found in river Okame, Busia, Uganda. The top soil does not contain much gold. - The gold panning with the Garrett Super Sluice on river Okame, Busia, Uganda

Mr. Wabwire, our sluice operator is gold panning with the Garrett Super Sluice on river Okame, Busia, Uganda…

Mr. Wabwire, our sluice operator is gold panning with the Garrett Super Sluice on river Okame, Busia, Uganda… - Wabwire gold panning on river Okame, Busia, Uganda

This is Wabwire, our staff member and sluice operator, here on the picture he is gold panning on the river Okame, Busia, Uganda.

This is Wabwire, our staff member and sluice operator, here on the picture he is gold panning on the river Okame, Busia, Uganda. - One pan prospecting volume

The one pan prospecting volume is shown on this picture. This is Garrett Backpacker Pan filled with soil. When this exact gold pan is filled little bit below its hole on the side, the volume is just about 1.2 liters. By knowing the specific density of the soil, and by knowing the volume and actual gold prospecting results, we may know if the recoverable gold is profitable in the soil. That is field laboratory.

The one pan prospecting volume is shown on this picture. This is Garrett Backpacker Pan filled with soil. When this exact gold pan is filled little bit below its hole on the side, the volume is just about 1.2 liters. By knowing the specific density of the soil, and by knowing the volume and actual gold prospecting results, we may know if the recoverable gold is profitable in the soil. That is field laboratory. - Gold prospecting on river Okame, Busia, Uganda

The river Okame does not have the exposed bedrock, yet it carries gold particles from overburden soil, and from tailings that are constantly spilled into the river. It also accrues the mercury waste from mining activities. Basic gold prospecting practice can be done on the river.

The river Okame does not have the exposed bedrock, yet it carries gold particles from overburden soil, and from tailings that are constantly spilled into the river. It also accrues the mercury waste from mining activities. Basic gold prospecting practice can be done on the river. - Gold nuggets on the hand

These are small gold nuggets directly from mother lode in Busia, Uganda.

These are small gold nuggets directly from mother lode in Busia, Uganda. - The engine for rudimentary ball mill in Uganda, East Africa

This is the engine used for rudimentary ball mill in Uganda, East Africa.

This is the engine used for rudimentary ball mill in Uganda, East Africa. - Rudimentary ball mill or "crusher" in Uganda

This is rudimentary ball mill or "crusher" in Uganda, it is used for primary crushing and final milling. Capacity is only 100 kg per hour.

This is rudimentary ball mill or "crusher" in Uganda, it is used for primary crushing and final milling. Capacity is only 100 kg per hour. - Rudimentary ball mill in Busia, Uganda

This is rudimentary ball mill in Busia, Uganda. People tend to use very big balls inside for the reason that they do not use primary crushing properly. Thus big ball helps that rocks get crushed. No liners are used and such rudimentary ball mills are broken each in a while, they don't last in operation longer than just few months when they need to get repaired. Dusty environment and improper maintenance contribute to low efficiency. The capacity is maximum 100 kg per hour.

This is rudimentary ball mill in Busia, Uganda. People tend to use very big balls inside for the reason that they do not use primary crushing properly. Thus big ball helps that rocks get crushed. No liners are used and such rudimentary ball mills are broken each in a while, they don't last in operation longer than just few months when they need to get repaired. Dusty environment and improper maintenance contribute to low efficiency. The capacity is maximum 100 kg per hour. - Rolex, the favorite food for many in Uganda, rolled chapati with eggs, that is Rolex

Rolex is favorite food for many in Uganda. Rolled chapati with eggs makes a Rolex!…

Rolex is favorite food for many in Uganda. Rolled chapati with eggs makes a Rolex!… - The bodaboda ride in Entebbe, Uganda

This is ride on bodaboda, the motorcycle in Entebbe, Uganda.

This is ride on bodaboda, the motorcycle in Entebbe, Uganda. - The view on the bed in Barconi hotel, Entebbe, Uganda

This is how the room and the bed looks like in Barconi Hotel, Entebbe, Uganda.

This is how the room and the bed looks like in Barconi Hotel, Entebbe, Uganda. - Barconi Hotel, Entebbe, Uganda

This is Barconi hotel in Entebbe, Uganda.

This is Barconi hotel in Entebbe, Uganda. - Quick bodaboda transfer of stuff in Entebbe, Uganda

Bodaboda people are motorcycle riders, and bodaboda is motorcycle. They transport everything, from luggage to beds and coffins with dead bodies. Bodaboda transport is always available everywhere in East Africa.

Bodaboda people are motorcycle riders, and bodaboda is motorcycle. They transport everything, from luggage to beds and coffins with dead bodies. Bodaboda transport is always available everywhere in East Africa. - Bus station in Busia, Uganda

This is the bus station in Busia town, Uganda.

This is the bus station in Busia town, Uganda. - Chapati preparation on streets of Busia, Uganda

This is how Ugandan chapati is being prepared directly on the street. It is very tasty food especially when hungry and there is nothing else around.

This is how Ugandan chapati is being prepared directly on the street. It is very tasty food especially when hungry and there is nothing else around. - Truck moving the ores to mineral processing place

This is how it looks like, the road is dusty, trucks are bringing ores to mineral processing places.

This is how it looks like, the road is dusty, trucks are bringing ores to mineral processing places. - Driving through Busia city in Uganda

This is Busia city and we are driving along the road.

This is Busia city and we are driving along the road. - Truck full of ore on its way to processing

This is small truck full of ore, we think it is loaded with about 2 tonnes of ore. It is called "one trip". One trip may contain from 0.50-1 grams to 4-5 grams of ore, if the ore have been taken from surface or represents overburden. If it is primary ore, it may contain 5-20 grams of gold and more.

This is small truck full of ore, we think it is loaded with about 2 tonnes of ore. It is called "one trip". One trip may contain from 0.50-1 grams to 4-5 grams of ore, if the ore have been taken from surface or represents overburden. If it is primary ore, it may contain 5-20 grams of gold and more. - Popular Mining Encyclopedia of Action Mining arrived to Uganda

The Popular Mining Encyclopedia as issued by Action Mining, finally arrived to Uganda. I had to push the postman to go by motorcycle to Tororo city, and come to Busia, so that I can get the encyclopedia into my hands. It contains such powerful information and plans for gold mining and recovery equipment.

The Popular Mining Encyclopedia as issued by Action Mining, finally arrived to Uganda. I had to push the postman to go by motorcycle to Tororo city, and come to Busia, so that I can get the encyclopedia into my hands. It contains such powerful information and plans for gold mining and recovery equipment. - Jean Louis in Busia

I am fetching money from the ATM machine in Busia, that was nice hot day before my departure to Europe.

I am fetching money from the ATM machine in Busia, that was nice hot day before my departure to Europe. - Your best weapon against terrorism

Your eyes are your best weapon against terrorism. Watch out, if you see anything suspicious report to authorities in Uganda.

Your eyes are your best weapon against terrorism. Watch out, if you see anything suspicious report to authorities in Uganda. - The warning issued in Busia, Uganda

This is one of the warnings that we can find in offices in Busia, Uganda where authorities are warning against bombs.

This is one of the warnings that we can find in offices in Busia, Uganda where authorities are warning against bombs. - Visit to SAMA Syanyonja Artisan Miners' Association in Busia, Uganda

This picture have been made few days after my visit to SAMA Syanyonja Artisan Miners' Alliance and demonstration mine promoting fairtrade gold, in association with EWAD and Fairtrade, where they state that they do not employ children in their mine.

This picture have been made few days after my visit to SAMA Syanyonja Artisan Miners' Alliance and demonstration mine promoting fairtrade gold, in association with EWAD and Fairtrade, where they state that they do not employ children in their mine. - Fancy insect passing over

This is nice fancy insect passing over. Is it going to convert to butterfly? We do not know. I just know I like it.

This is nice fancy insect passing over. Is it going to convert to butterfly? We do not know. I just know I like it. - Children in Uganda

These children we met playing on the mining site. That sounds dangerous and it is. Yet we cannot control families and their children and mining site was not under our control. We did warn them to take care and be careful. They liked our visit.

These children we met playing on the mining site. That sounds dangerous and it is. Yet we cannot control families and their children and mining site was not under our control. We did warn them to take care and be careful. They liked our visit. - The excavated open pit

This is excavated open pit that was explored by artisanal miners some years before. Small number of miners are still working in this area and recovering gold every day. Majority of them abandoned the sites and went to new gold rush locations.

This is excavated open pit that was explored by artisanal miners some years before. Small number of miners are still working in this area and recovering gold every day. Majority of them abandoned the sites and went to new gold rush locations. - Mr. Louis in front of the open pit

The open pit behind me is possible gold mining opportunity that we may explore in soonest future.

The open pit behind me is possible gold mining opportunity that we may explore in soonest future. - Previous mining locations

On these locations many artisanal miners have previously recovered gold and lived from it. Today many are still there even though the majority of miners abandoned the place and went somewhere else. So is the gold rush in Uganda.

On these locations many artisanal miners have previously recovered gold and lived from it. Today many are still there even though the majority of miners abandoned the place and went somewhere else. So is the gold rush in Uganda. - Dirty feet

Those are my dirty feet and shoes in Uganda.

Those are my dirty feet and shoes in Uganda. - Travel to prospecting location in Uganda

This is picture of our travel today on 15th January 2018 to the new prospecting and prospective location. On such new location we have gold mining opportunity to obtain new ores and process it. The location was occupied by artisanal miners before some years.

This is picture of our travel today on 15th January 2018 to the new prospecting and prospective location. On such new location we have gold mining opportunity to obtain new ores and process it. The location was occupied by artisanal miners before some years. - Preparation of rudimentary sluice for ore processing in Uganda

This is rudimentary sluice that is being prepared by our neighboring miners. In my opinion this type of the sluice is way to wide, not evenly balanced, with too steep slopes, and too high to load it with the ores. We cannot recommend small scaler miners and artisanal miners to make this type of sluices. That is inefficient as it requires much energy, material will not be evenly spread and gold would be lost.

This is rudimentary sluice that is being prepared by our neighboring miners. In my opinion this type of the sluice is way to wide, not evenly balanced, with too steep slopes, and too high to load it with the ores. We cannot recommend small scaler miners and artisanal miners to make this type of sluices. That is inefficient as it requires much energy, material will not be evenly spread and gold would be lost. - Mr. Okedi collecting concentrates from looped carpets

Looped carpets or miners' moss or 3M Nomad type of a carpets are used to efficiently recover gold larger than 50 mesh, gold nuggets, flakes and larger gold. On the end of the day and multiple times of day, concentrates are collected from such carpets.

Looped carpets or miners' moss or 3M Nomad type of a carpets are used to efficiently recover gold larger than 50 mesh, gold nuggets, flakes and larger gold. On the end of the day and multiple times of day, concentrates are collected from such carpets. - Mr. Louis doing practical field assay of gold

Mr. Louis is doing here practical field assay of gold content in some soil. Similar method may be used to concentrate gold from the operation and to determine how much was recovered.

Mr. Louis is doing here practical field assay of gold content in some soil. Similar method may be used to concentrate gold from the operation and to determine how much was recovered. - Magnified flat gold nugget in the gold pan

This is magnified and flat gold nugget in the pan. It is probably flat due to the previous ball mill processing, it was smashed and became flat.

This is magnified and flat gold nugget in the pan. It is probably flat due to the previous ball mill processing, it was smashed and became flat. - Small nuggets recovered

Small flat nuggets are also found in concentrates and recovered by using super-concentration and simple gold panning methods.

Small flat nuggets are also found in concentrates and recovered by using super-concentration and simple gold panning methods. - Mercury gold and mercury ball in the gold pan

This is how it looks like when many gold particles are connected or amalgamated together with mercury. Miners used mercury in recovery of gold, and lost it in heaps of tailings. We are recovering both the mercury and the gold from such tailings, without using new mercury or introducing new mercury in the process.

This is how it looks like when many gold particles are connected or amalgamated together with mercury. Miners used mercury in recovery of gold, and lost it in heaps of tailings. We are recovering both the mercury and the gold from such tailings, without using new mercury or introducing new mercury in the process. - The mercury gold once again

This is mercury gold once again shown in the gold pan after fine gold concentration process. We do not use mercury, we recover it as side effect.

This is mercury gold once again shown in the gold pan after fine gold concentration process. We do not use mercury, we recover it as side effect. - Mercury recovered from concentrates

Instead of nice yellow gold, our gold looks as silver like, as it is mixed with mercury. Heaps of tailings are polluted with mercury and our recovery is such that we cannot see it yellow any more unless it is either microscopic, as such could not be connected to mercury or too large as nugget, as such also did not connect to mercury.

Instead of nice yellow gold, our gold looks as silver like, as it is mixed with mercury. Heaps of tailings are polluted with mercury and our recovery is such that we cannot see it yellow any more unless it is either microscopic, as such could not be connected to mercury or too large as nugget, as such also did not connect to mercury. - The fine gold recovery system

This is fine gold recovery system that helps us concentrate all the gold smaller than 50 mesh.

This is fine gold recovery system that helps us concentrate all the gold smaller than 50 mesh. - Gold is recovered in form of mercury

Heaps of tailings are polluted by mercury from previous mining operation. We are recovering mercury as well with the gold, and later dispose safely with the pollutant. Mercury is not used in our operation. We recover mercury from nature.

Heaps of tailings are polluted by mercury from previous mining operation. We are recovering mercury as well with the gold, and later dispose safely with the pollutant. Mercury is not used in our operation. We recover mercury from nature. - Fine gold recovery system

This is fine gold recovery systems, we are using the genious methods invented by smart microscopist from Oregon for purposes of mercury free gold recovery.

This is fine gold recovery systems, we are using the genious methods invented by smart microscopist from Oregon for purposes of mercury free gold recovery. - Concentrate is being processed

Mr. Louis is processing the remaining concentrates and process is fast. It is possible to process multiple buckets of concentrates after work, and to get to the fine gold within 15 minutes.

Mr. Louis is processing the remaining concentrates and process is fast. It is possible to process multiple buckets of concentrates after work, and to get to the fine gold within 15 minutes. - The gold recovery system

This is view from my working place on the gold recovery system for all gold smaller than 50 mesh, down to 5 microns. This fine gold can be recovered, totally without using mercury and by using simplest set theory in mathematics applied practically. Many people make a question how a set theory may be applied practically, and that is exactly how our gold recovery system works, by using the set theory and by removing those parts of material not containing or containing gold.

This is view from my working place on the gold recovery system for all gold smaller than 50 mesh, down to 5 microns. This fine gold can be recovered, totally without using mercury and by using simplest set theory in mathematics applied practically. Many people make a question how a set theory may be applied practically, and that is exactly how our gold recovery system works, by using the set theory and by removing those parts of material not containing or containing gold. - Buckets of concentrate are today processed for gold

The buckets of concentrate are today processed for gold. In general, our bulk of concentrate is not large. These many buckets contain various particle sizes and types of gold, and help in sorting out what we were doing. We can then determine which heap of tailing was better productive.

The buckets of concentrate are today processed for gold. In general, our bulk of concentrate is not large. These many buckets contain various particle sizes and types of gold, and help in sorting out what we were doing. We can then determine which heap of tailing was better productive. - Children panning for gold on mining site

These children are panning for gold on mining site in a dangerous and polluted environment. Each heap of tailings is polluted with mercury. Children are in constant contact with mercury while playing and working on the mining site. We do not endorse such activities. This is report from neighboring sites where we do not have control.

These children are panning for gold on mining site in a dangerous and polluted environment. Each heap of tailings is polluted with mercury. Children are in constant contact with mercury while playing and working on the mining site. We do not endorse such activities. This is report from neighboring sites where we do not have control. - Heaps of tailings being milled again and processed

These heaps of tailings are being milled again with the rudimentary locally made hammer crusher that runs in wet mode. The material is then processed on small looped carpet sluices. The hammer crusher is spending about 25,000 Ugs. per day on hammers alone, which is about US $6.95.

These heaps of tailings are being milled again with the rudimentary locally made hammer crusher that runs in wet mode. The material is then processed on small looped carpet sluices. The hammer crusher is spending about 25,000 Ugs. per day on hammers alone, which is about US $6.95. - Buckets of concentrate on the end of the day

The buckets of concentrates are collected on the end of the day. The picture is dark for that reason that it was evening without light.

The buckets of concentrates are collected on the end of the day. The picture is dark for that reason that it was evening without light. - Mercury coated gold have silver color

This is mercury coated gold, and it has a shiny silver color.

This is mercury coated gold, and it has a shiny silver color. - Gold nuggets magnified in the gold pan

These gold nuggets are magnified 10x in the gold pan.

These gold nuggets are magnified 10x in the gold pan. - Types of gold nuggets recovered

Here are small gold nuggets recovered in concentrate of today.

Here are small gold nuggets recovered in concentrate of today. - Type of small gold nuggets we are recovering

This is one type of small gold nuggets we are recovering from heaps of tailings in Uganda.

This is one type of small gold nuggets we are recovering from heaps of tailings in Uganda. - Coarse gold or smallest gold nuggets are found

In the previous concentrate we found multiple nuggets of 1-4 millimeter mostly of flake shape due to ball hammering them flat in ball mills.

In the previous concentrate we found multiple nuggets of 1-4 millimeter mostly of flake shape due to ball hammering them flat in ball mills. - Dish wash to settle finest gold particles down from the surface of water

The dish wash is used to settle finest gold particles down into the water as they may float and go out during the gold panning verification.

The dish wash is used to settle finest gold particles down into the water as they may float and go out during the gold panning verification. - Mr. Louis filling the drum of water

The drum is filled with water for the verification of gold collection in 2 hours of work. We are making scientific yet practical and field measurements of gold recovery.

The drum is filled with water for the verification of gold collection in 2 hours of work. We are making scientific yet practical and field measurements of gold recovery. - Purchasing manager verifying gold particles on the sluice

Purchasing manager is verifying the gold particles on the sluice.

Purchasing manager is verifying the gold particles on the sluice. - Mr. Louis in front of the heap of tailings

This heap of tailings was processed as of the day of publishing of this picture.

This heap of tailings was processed as of the day of publishing of this picture. - Small heap of tailings

This heap of tailings is being processed as of the day of publishing this image.

This heap of tailings is being processed as of the day of publishing this image. - Mr. Louis with tailings heaps in background

Tailings are visible in background, heaps of tailings to be processed with our fine gold recovery sluices.

Tailings are visible in background, heaps of tailings to be processed with our fine gold recovery sluices. - Tailings in background

One may see many tailings heaps in background. Each of them contains fine gold.

One may see many tailings heaps in background. Each of them contains fine gold. - Tailings heaps in background on mineral processing site

One may see people working on this mineral processing site with tailings heaps in background. Well, those are ours. We process those heaps.

One may see people working on this mineral processing site with tailings heaps in background. Well, those are ours. We process those heaps. - Mr. Okedi feeding the sluice

Mr. Okedi is feeding the sluice here, few cubic meters have been handled within 5 hours of work.

Mr. Okedi is feeding the sluice here, few cubic meters have been handled within 5 hours of work. - The nugget in comparison to my finger

This gold nugget is small and may be seen here in comparison to my finger. It was recovered by using special matting. Multiple nuggets were recovered, many of them coated with mercury in silver color and many of them as pure gold.

This gold nugget is small and may be seen here in comparison to my finger. It was recovered by using special matting. Multiple nuggets were recovered, many of them coated with mercury in silver color and many of them as pure gold. - Gold nugget of 2-3 mm under magnification

This small gold nugget has size of 2-3 millimeter, and is magnified for 10x by using the jeweler's loupe and a simple mobile phone camera. It was recovered by using special matting on our sluice in Uganda.

This small gold nugget has size of 2-3 millimeter, and is magnified for 10x by using the jeweler's loupe and a simple mobile phone camera. It was recovered by using special matting on our sluice in Uganda. - Fine gold particles

These fine gold particles appear silver like color on this picture, but they were in fact yellow. When magnified under the lack of the light, the mobile phone is giving somehow distorted image.

These fine gold particles appear silver like color on this picture, but they were in fact yellow. When magnified under the lack of the light, the mobile phone is giving somehow distorted image. - Preparing the sluice for work

Mr. Louis is here preparing the sluice for work. Some key details are not shown on the picture, and are rather revealed to clients in the Start Your Own Gold Mine program. This is testing sluice whereby we are testing the capability to recover gold by at least 98% and where we are determining what else need to be improved for the actual sluice to be constructed.

Mr. Louis is here preparing the sluice for work. Some key details are not shown on the picture, and are rather revealed to clients in the Start Your Own Gold Mine program. This is testing sluice whereby we are testing the capability to recover gold by at least 98% and where we are determining what else need to be improved for the actual sluice to be constructed. - The sluice setup on January 11th 2018

This is our sluice setup on January 11th 2018. We are definitely able to recover gold nuggets and fine gold particles.

This is our sluice setup on January 11th 2018. We are definitely able to recover gold nuggets and fine gold particles. - Administration before the daily work

We always have administrative tasks to do, before, during and after the work. We record, measure, notify, obtain receipts, demand signatures, and do whatever necessary administration tasks.

We always have administrative tasks to do, before, during and after the work. We record, measure, notify, obtain receipts, demand signatures, and do whatever necessary administration tasks. - Concentrate collection

On the end of the day, concentrate is collected and retained for further concentration and final gold recovery.

On the end of the day, concentrate is collected and retained for further concentration and final gold recovery. - Miners working on the sluice

Miners are handling the first tailings heaps on this mining site.

Miners are handling the first tailings heaps on this mining site. - Women and people panning for gold nearby our tailings heaps

These women and men are panning for gold just nearby our tailings heaps. They may obtain per day of panning from 0.1 to 0.3 grams of gold, or sometimes more. It helps them live the life.

These women and men are panning for gold just nearby our tailings heaps. They may obtain per day of panning from 0.1 to 0.3 grams of gold, or sometimes more. It helps them live the life. - Mining and mineral processing site

This is our mining and mineral processing site where we have agreement to process all the tailings heaps.

This is our mining and mineral processing site where we have agreement to process all the tailings heaps. - Miners feeding the sluice

Sluice is fed by miners by the rate of 132 shovels per hour where average shovel is about 8 kilograms, amounting to little bit more than one tonne per hour. In the first stage, slow water pressure and low slope is applied to review how much of gold is retained and what gold is eventually being lost. Once capability have been attained, the slope is increasing up to the tolerated degree, and water pressure is increased. Up to 6-8 tonnes per hour may then be handled in the second stage.

Sluice is fed by miners by the rate of 132 shovels per hour where average shovel is about 8 kilograms, amounting to little bit more than one tonne per hour. In the first stage, slow water pressure and low slope is applied to review how much of gold is retained and what gold is eventually being lost. Once capability have been attained, the slope is increasing up to the tolerated degree, and water pressure is increased. Up to 6-8 tonnes per hour may then be handled in the second stage. - Concentrate on the vortex matting

This is vortex matting, enlarged. Concentrate is under the surface of these particles, including several small gold nuggets.

This is vortex matting, enlarged. Concentrate is under the surface of these particles, including several small gold nuggets. - Mr. Louis by the sluice

This is Mr. Louis, preparing small details for the fine gold recovery sluice. Gold particles are so small that cannot be seen by naked eyes.

This is Mr. Louis, preparing small details for the fine gold recovery sluice. Gold particles are so small that cannot be seen by naked eyes. - Water pump is debugged

The water pump could not pull the water on 2-3 meters. We found out that pressure was disturbed too weak connection of the suction hose. Within few minutes it was repaired and water pump engaged.

The water pump could not pull the water on 2-3 meters. We found out that pressure was disturbed too weak connection of the suction hose. Within few minutes it was repaired and water pump engaged. - Our purchasing manager on the site

This is our purchasing manager in Uganda, she handles a lot of accounting, facilitates with suppliers, makes sure that things are running smoothly.

This is our purchasing manager in Uganda, she handles a lot of accounting, facilitates with suppliers, makes sure that things are running smoothly. - Quick and improvized sluice ready for work

This is quick and improvized sluice ready for work and handling of the tailings heaps.

This is quick and improvized sluice ready for work and handling of the tailings heaps. - Preparing the elevation for sluices

Mr. Okedi is preparing the elevation for the sluice hopper.

Mr. Okedi is preparing the elevation for the sluice hopper. - Old welding clamps used for carpentry

This type of welding clamps may be used for carpentry and are generally useful to clamp the prospecting equipment, such as sluices together.

This type of welding clamps may be used for carpentry and are generally useful to clamp the prospecting equipment, such as sluices together. - Using welding clamps for carpentry

These welding clamps may be used for simple carpentry as one can see it.

These welding clamps may be used for simple carpentry as one can see it. - Preparation of the HDPE pipes

The HDPE (High Density Polyethylene) pipe is prepared on the mining site for the sluice run.

The HDPE (High Density Polyethylene) pipe is prepared on the mining site for the sluice run. - Gold particles on the rock

This magnification of 10x shows gold particles of 3-4 millimeter on the rock that also contains some iron or black sand.

This magnification of 10x shows gold particles of 3-4 millimeter on the rock that also contains some iron or black sand. - Repairing the wooden goat

Those wooden goats were made of low quality timber. Not made to last, but to be light and to endure the improvization stage. We had to repair this one.

Those wooden goats were made of low quality timber. Not made to last, but to be light and to endure the improvization stage. We had to repair this one. - The old abandoned rudimentary ball mill drum

This is old and abandoned rudimentary ball mill drum on the mining site. One may see how it was repaired multiple times. We suspect gold inside, left for those who know where to search for it.

This is old and abandoned rudimentary ball mill drum on the mining site. One may see how it was repaired multiple times. We suspect gold inside, left for those who know where to search for it. - Workers preparing bench and desks as open-air furniture

These workers are making outside furniture, or open-air furniture, the improvized benches, desks, and kitchen furniture. The mining camp requires such.

These workers are making outside furniture, or open-air furniture, the improvized benches, desks, and kitchen furniture. The mining camp requires such. - Collecting and separating the black sand

We are using properly our technology to collect and separate black sand, that is what these boys are doing. They are classifying and collecting black sand.

We are using properly our technology to collect and separate black sand, that is what these boys are doing. They are classifying and collecting black sand. - The rock crusher, rudimentary batch ball mill

This is the rock crusher. In Swahili in Tanzania, this crusher is known as calasher. It is a rudimentary ball mill made in Uganda. But we are in Uganda now, and this rock crusher has 33 rotations per minute and may crush about 100 kilograms per hour. Handling it and operation is dangerous. Injuries happen. And the crusher itself may run out of its stand, and start rotating on the mining site. And kill somebody. That happened already. But not on our mining site. Thus crusher is used in Uganda on the…

This is the rock crusher. In Swahili in Tanzania, this crusher is known as calasher. It is a rudimentary ball mill made in Uganda. But we are in Uganda now, and this rock crusher has 33 rotations per minute and may crush about 100 kilograms per hour. Handling it and operation is dangerous. Injuries happen. And the crusher itself may run out of its stand, and start rotating on the mining site. And kill somebody. That happened already. But not on our mining site. Thus crusher is used in Uganda on the… - Mineral sample on the mining site

This is gold bearing rock that is crushed, milled and processed on this mining site.

This is gold bearing rock that is crushed, milled and processed on this mining site. - Mr. Louis nearby the tailings heap

This is the tailings heap in background, and Mr. Louis is watching what? Birds? We don't know.

This is the tailings heap in background, and Mr. Louis is watching what? Birds? We don't know. - The mercury coated or amalgamated gold in the gold pan

This is the enlargement of the mercury coated or amalgamated gold in the gold pan.

This is the enlargement of the mercury coated or amalgamated gold in the gold pan. - Mercury gold and small gold particles recovered

Mercury gold is seen in the gold pan and represents the result from one portion of the concentrates that were collected on the sluice. Mercury collects small particles of gold together, and we recovery mercury and dispose of it. We do not use mercury in recovery of the gold. We recover both gold and mercury accidentally due to previous mercury pollution.

Mercury gold is seen in the gold pan and represents the result from one portion of the concentrates that were collected on the sluice. Mercury collects small particles of gold together, and we recovery mercury and dispose of it. We do not use mercury in recovery of the gold. We recover both gold and mercury accidentally due to previous mercury pollution. - Sluice handling

People are handling the sluice for fine gold recovery. We are using 4 important pieces of technology necessary to capture small gold. The test stage allows a lot of mistakes to happen, so that next sluice may be built with all the small improvements necessary for better gold recovery.

People are handling the sluice for fine gold recovery. We are using 4 important pieces of technology necessary to capture small gold. The test stage allows a lot of mistakes to happen, so that next sluice may be built with all the small improvements necessary for better gold recovery. - Feeding the sluice

The sluice is fed during the first half an hour of testing. Clay material was much harder to handle, while all the sand was handled pretty well, mercury and gold particles could be recovered, together with the oxide coated gold particles.

The sluice is fed during the first half an hour of testing. Clay material was much harder to handle, while all the sand was handled pretty well, mercury and gold particles could be recovered, together with the oxide coated gold particles. - Laminar water flow

Laminar water flow on the sluice is important factor in gold recovery. Turbulences and bubbles or air spaces under the water flow shall by all means be avoided.

Laminar water flow on the sluice is important factor in gold recovery. Turbulences and bubbles or air spaces under the water flow shall by all means be avoided. - Gold particles are separated on the sluice

Sluice and the slick plates on the first part of the sluice are being separated from each other and gold particles are running to be captured. Water flow is carefully observed, the level of the sluice, bubbles and turbulences.

Sluice and the slick plates on the first part of the sluice are being separated from each other and gold particles are running to be captured. Water flow is carefully observed, the level of the sluice, bubbles and turbulences. - So many hoses, pipe, which one is ours?

There are so many hoses and pipes on the ground, many of them are neglected. Miners do their best. Due to expenses, light blue hoses are used to bring water. But they are also breaking all the time and are more liability than an asset. We are using the HDPE pipe of two inch as it is durable and gives least resistant to water in comparison to those other soft hoses.

There are so many hoses and pipes on the ground, many of them are neglected. Miners do their best. Due to expenses, light blue hoses are used to bring water. But they are also breaking all the time and are more liability than an asset. We are using the HDPE pipe of two inch as it is durable and gives least resistant to water in comparison to those other soft hoses. - The HDPE pipe is being moved for easier water supply

The HDPE pipe is moved by our people for easier water supply. That way we did not need to cut the expensive suction hose which we use to bring water from the HDPE pipe. HDPE means high density polyethylene. Polyethylene is a lightweight thermoplastic used in insulation, plumbing and similar applications.

The HDPE pipe is moved by our people for easier water supply. That way we did not need to cut the expensive suction hose which we use to bring water from the HDPE pipe. HDPE means high density polyethylene. Polyethylene is a lightweight thermoplastic used in insulation, plumbing and similar applications. - The sluice ready for the tailings heap test

The sluice is setup on the mining site on 1st January 2018 and is ready for the tailings test. Larger gold particles were found and much of the smaller particles of black, brown and dark red gold. Maybe you wonder what is black, brown and dark red gold? Those gold particles are coated with other minerals and do not appear as yellow and shiny as larger gold particles.

The sluice is setup on the mining site on 1st January 2018 and is ready for the tailings test. Larger gold particles were found and much of the smaller particles of black, brown and dark red gold. Maybe you wonder what is black, brown and dark red gold? Those gold particles are coated with other minerals and do not appear as yellow and shiny as larger gold particles. - The polluted feces of the skinned goat

The polluted feces of the skinned goat contains a lot of plastic. Goats were eating whatever they found around. It was not a witchcraft. It was polluted environment.

The polluted feces of the skinned goat contains a lot of plastic. Goats were eating whatever they found around. It was not a witchcraft. It was polluted environment. - Skinned goat, and polluted with plastic

The goat is skinned for feast, yet polluted with plastic. A person asked me to come there to ask me something, and I came. I said by joke it is witchcraft. But the guy really was thinking it is. What happened is that they found some plastic in the goat. Due to the environment polluted with plastic, the goat had stomach full of it.

The goat is skinned for feast, yet polluted with plastic. A person asked me to come there to ask me something, and I came. I said by joke it is witchcraft. But the guy really was thinking it is. What happened is that they found some plastic in the goat. Due to the environment polluted with plastic, the goat had stomach full of it. - Funny looking rooster

This funny looking rooster we found in Tororo, while purchasing the HDPE (High Density Polyethylene) pipe connectors and other small stuff necessary for business.

This funny looking rooster we found in Tororo, while purchasing the HDPE (High Density Polyethylene) pipe connectors and other small stuff necessary for business. - Tororo rock in Tororo city, Uganda

This is well known Tororo rock in the Tororo city in southeastern Uganda. It emerges there out of nothing, and no other hills are visible in the area.

This is well known Tororo rock in the Tororo city in southeastern Uganda. It emerges there out of nothing, and no other hills are visible in the area. - Gold nugget

This gold nugget was recovered by panning.

This gold nugget was recovered by panning. - Gold nugget on my hand

This is yet another smaller gold nugget on my hand.

This is yet another smaller gold nugget on my hand. - A gold nugget on the prospecting sluice

One gold nugget may be seen on the prospecting sluice.

One gold nugget may be seen on the prospecting sluice. - 0.89 grams of gold on the pocket scale

This gold was collected with one of our sluice that helped in fine gold recovery.

This gold was collected with one of our sluice that helped in fine gold recovery. - 11.42 grams of gold before the end of the shift

11.42 grams of gold were recovered this day before the end of the shift. This gold contains dangerous mercury, which we do not endorse or use. It was recovered with some of our help, but miners used their own methods. Mercury is dangerous chemical and not advisable for anything. It shall be disposed as waste.

11.42 grams of gold were recovered this day before the end of the shift. This gold contains dangerous mercury, which we do not endorse or use. It was recovered with some of our help, but miners used their own methods. Mercury is dangerous chemical and not advisable for anything. It shall be disposed as waste. - 6.44 grams of gold recovered on the sluice

The black nylon part of the sluice with a wooden stopper has helped to recover these 6.44 grams of gold. It means, no other technology was used, just a stopper to stop the majority of gold to go over to the sluice.

The black nylon part of the sluice with a wooden stopper has helped to recover these 6.44 grams of gold. It means, no other technology was used, just a stopper to stop the majority of gold to go over to the sluice. - Mr. Louis after the work

The picture was made after the work. Mr. Louis is moving with the equipment to the side.

The picture was made after the work. Mr. Louis is moving with the equipment to the side. - Gold nuggets recovered on 18th December 2017

These are beautiful gold nuggets. Picture is slightly changed in its tone.

These are beautiful gold nuggets. Picture is slightly changed in its tone. - The flow on the sluice

The narrow sluice is captuing a lot of fine gold.

The narrow sluice is captuing a lot of fine gold. - Fine gold is captured

This setup is capturing fine gold particles.

This setup is capturing fine gold particles. - The improved super-concentration of gold concentrates

This is improved super-concentration of gold concentrates. The traditional sluice is simply extended with the technology we use to capture the finest gold particles.

This is improved super-concentration of gold concentrates. The traditional sluice is simply extended with the technology we use to capture the finest gold particles. - 0.11 grams of gold nuggets on the pocket scale

These gold nuggets were recovered by sluicing and gold panning.

These gold nuggets were recovered by sluicing and gold panning. - 4.79 grams of gold on the pocket scale

This gold was recovered on 18th December 2017.

This gold was recovered on 18th December 2017. - 4.44 grams of gold on the pocket scale

This gold was recovered on 18th December 2017…

This gold was recovered on 18th December 2017… - 0.37 grams of gold on the pocket scale

This is 0.37 grams of gold on the pocket scale.

This is 0.37 grams of gold on the pocket scale. - This is mercury gold and gold nuggets

One may see on the left side the gold recovered by mercury which is of silver color and few gold yellow gold nuggets on the right side recovered on the sluice and by gold panning. We do not endorse any mercury recoveries.

One may see on the left side the gold recovered by mercury which is of silver color and few gold yellow gold nuggets on the right side recovered on the sluice and by gold panning. We do not endorse any mercury recoveries. - Gold nuggets

These gold nuggets are not as heavy, they are enlarged in the image, and were recovered today on 18th December 2017.

These gold nuggets are not as heavy, they are enlarged in the image, and were recovered today on 18th December 2017. - Gold nuggets, macro picture

This is yet another picture of smaller gold nuggets recovered by gold panning and concentration on the sluice.

This is yet another picture of smaller gold nuggets recovered by gold panning and concentration on the sluice. - Gold nugget in a gold pan

This is gold nugget.

This is gold nugget. - Gold nuggets in a gold pan

My gold pan is scratched. Yet we can recover gold nuggets as these.

My gold pan is scratched. Yet we can recover gold nuggets as these. - Gold nugget on my hand

This gold nugget was recovered on this day of 18th December 2017 by gold panning.

This gold nugget was recovered on this day of 18th December 2017 by gold panning. - Miners' Moss or spaghetti carpet

This type of miners's moss or spaghetti carpets are used to capture fine gold. That is certainly not the best solution, yet it is used to created kilograms of gold in Uganda.

This type of miners's moss or spaghetti carpets are used to capture fine gold. That is certainly not the best solution, yet it is used to created kilograms of gold in Uganda. - The rudimentary sluice is being upgraded

This rudimentary sluice is being upgraded with piece of technology that may capture finest gold particles. Yet only with the proper setup the majority of gold may be recovered. The water pressure cannot be too much, material cannot be washed to fast. There are many other factors influencing the gold recovery rate.

This rudimentary sluice is being upgraded with piece of technology that may capture finest gold particles. Yet only with the proper setup the majority of gold may be recovered. The water pressure cannot be too much, material cannot be washed to fast. There are many other factors influencing the gold recovery rate. - Gold nugget directly recovered on the sluice

This gold nugget was directly recovered on the sluice on the nylon, while washing the concentrated material. It represents the lack of riffles or proper sluice to recover such nuggets.

This gold nugget was directly recovered on the sluice on the nylon, while washing the concentrated material. It represents the lack of riffles or proper sluice to recover such nuggets. - This is fine gold under the magnifier

This is fine gold, many particles of fine gold are seen under the magnifier and image captured by mobile phone.

This is fine gold, many particles of fine gold are seen under the magnifier and image captured by mobile phone. - Fine gold line

This is the line of fine gold under the magnifier.

This is the line of fine gold under the magnifier. - Fine gold particles concentrated on the sluice

The local sluice allows one to observe the finest gold particles being concentrated on the first part of the sluice.

The local sluice allows one to observe the finest gold particles being concentrated on the first part of the sluice. - The piece of black nylon is showing fine gold

This piece of black nylon have been mounted on the gold washing sluice and is being washed with pretty clean water from the nearest river Okame in Uganda. On such nice piece of black nylon, one may see how finest gold particles are being concentrated.

This piece of black nylon have been mounted on the gold washing sluice and is being washed with pretty clean water from the nearest river Okame in Uganda. On such nice piece of black nylon, one may see how finest gold particles are being concentrated. - Gold particles with mercury

The tailing as being produced by artisanal miners in Uganda contains a lot of mercury inside and thus gold is recovered that contain a lot of mercury. It is not yellow but of silver color. We do not endorse usage of mercury in mining operations. However, we do recover gold that may contain mercury or traces of mercury. Such mercury, when recovered by our company, is disposed and exported as waste to secure locations.

The tailing as being produced by artisanal miners in Uganda contains a lot of mercury inside and thus gold is recovered that contain a lot of mercury. It is not yellow but of silver color. We do not endorse usage of mercury in mining operations. However, we do recover gold that may contain mercury or traces of mercury. Such mercury, when recovered by our company, is disposed and exported as waste to secure locations. - Mr. Louis showing the gold nuggets to the miner

Mr. Louis is showing the gold nuggets to the miner, after demonstrating him the classification process. Gold nuggets may be easily recovered once classification of concentrate have been finished.

Mr. Louis is showing the gold nuggets to the miner, after demonstrating him the classification process. Gold nuggets may be easily recovered once classification of concentrate have been finished. - Gold nugget in the gold pan

The gold nugget in the gold pan was panned by myself after the classification of particles into 3 separate sizes, larger than 20 mesh, particles between 20 and 30 mesh, and particles smaller than 30 mesh. After such classification of particle sizes, it was a matter of few minutes to pan out the larger gold nuggets.

The gold nugget in the gold pan was panned by myself after the classification of particles into 3 separate sizes, larger than 20 mesh, particles between 20 and 30 mesh, and particles smaller than 30 mesh. After such classification of particle sizes, it was a matter of few minutes to pan out the larger gold nuggets. - Basins are never enough

One of the out-points or better say not logical facts that we found on this mining site is the lack of basins and containers for the concentrates and handling of concentrates. Buckets were completely missing. Basins were not in best shapes. So every single action is coping or exchanging with other basins containing always some gold inside. It creates new risks in handling gold and delays the operation.

One of the out-points or better say not logical facts that we found on this mining site is the lack of basins and containers for the concentrates and handling of concentrates. Buckets were completely missing. Basins were not in best shapes. So every single action is coping or exchanging with other basins containing always some gold inside. It creates new risks in handling gold and delays the operation. - Gold nugget recovered by simple panning

After washing the concentrates as created by neighbor, all the details of such concentrates have been analyzed. The procedure have been tested and devised which would be the best to collect simply all of the gold. The concentrate was such that it could contain even 3 grams big gold nuggets, which we did not find today. It contains a lot of fine gold due to the accumulation of black sands found in spaghetti carpets or miners' moss, and it contains a lot of smaller nuggets of the size of about 30-60…

After washing the concentrates as created by neighbor, all the details of such concentrates have been analyzed. The procedure have been tested and devised which would be the best to collect simply all of the gold. The concentrate was such that it could contain even 3 grams big gold nuggets, which we did not find today. It contains a lot of fine gold due to the accumulation of black sands found in spaghetti carpets or miners' moss, and it contains a lot of smaller nuggets of the size of about 30-60… - Mercury gold recovery is dangerous and poisonous business

Mercury is a dangerous substance which we do not recommend to anybody in mining operations. There are many good mercury free gold recovery methods. Why pay for mercury when gold can be recovered without mercury? No American or European gold prospector is using mercury in their operations. So just stop using it, stop getting sick and stop polluting your environment.

Mercury is a dangerous substance which we do not recommend to anybody in mining operations. There are many good mercury free gold recovery methods. Why pay for mercury when gold can be recovered without mercury? No American or European gold prospector is using mercury in their operations. So just stop using it, stop getting sick and stop polluting your environment. - Miners feeding the hammer crusher in background

Those two miners in background are feeding the hammer crusher while I am handling the super concentrate.

Those two miners in background are feeding the hammer crusher while I am handling the super concentrate. - Helping the neighbor

The super-concentration and handling of concentrates for the neighbor helped me understand much about the operation, the soil, the tailing and gold inside. It was not all how I have expected it. One need to see it practically, to understand what is required to handle such soil. There are factors that are important to note: - the type of machinery that people are using to create such tailings, - the particle sizes that such machinery is producing, - the particles sizes of gold that such machinery…

The super-concentration and handling of concentrates for the neighbor helped me understand much about the operation, the soil, the tailing and gold inside. It was not all how I have expected it. One need to see it practically, to understand what is required to handle such soil. There are factors that are important to note: - the type of machinery that people are using to create such tailings, - the particle sizes that such machinery is producing, - the particles sizes of gold that such machinery… - USAID tent with "free vaccination" for Ugandan people

This is the USAID tent in Busia, Uganda. They offer "free vaccinations" for Ugandan people. No information was specified neither possible to be given of the content of those vaccines. Myself, I know that Bill Gates is supporter of this organization and also supporter of the solutions to "over population" problems. Once in front of thousands of people he mentioned how such problems of over population are solved by using vaccinations. Does that mean vaccination are endangering people's health? One…

This is the USAID tent in Busia, Uganda. They offer "free vaccinations" for Ugandan people. No information was specified neither possible to be given of the content of those vaccines. Myself, I know that Bill Gates is supporter of this organization and also supporter of the solutions to "over population" problems. Once in front of thousands of people he mentioned how such problems of over population are solved by using vaccinations. Does that mean vaccination are endangering people's health? One… - Busia Town Baptist Church in Uganda

Read the wordings for yourself and make your own conclusions.

Read the wordings for yourself and make your own conclusions. - Ugandan bicycle transport

The Ugandan bicycle transport is very interesting. Almost everything may be transported by bicycles, including coffins, goats, pigs, 20 meter long heavy wires, large wooden sheets, beds, Coca-Cola boxes, and 20-30 plastic chairs. Just anything goes for 500 to 2,000 Ugs. per round.

The Ugandan bicycle transport is very interesting. Almost everything may be transported by bicycles, including coffins, goats, pigs, 20 meter long heavy wires, large wooden sheets, beds, Coca-Cola boxes, and 20-30 plastic chairs. Just anything goes for 500 to 2,000 Ugs. per round. - Diesel and benzin prices in Uganda on 3rd December 2017

The diesel price on 3rd December 2017 was 3000 Ugandan schillings or US $0.82 per liter, while benzin price was 3550 Ugs. or US $0.97 per liter.

The diesel price on 3rd December 2017 was 3000 Ugandan schillings or US $0.82 per liter, while benzin price was 3550 Ugs. or US $0.97 per liter. - View from the Emirates guest house in Busia, Uganda

This is how Busia town looks like. The view is from a second floor of the Emirates guest house in Busia, Uganda.

This is how Busia town looks like. The view is from a second floor of the Emirates guest house in Busia, Uganda. - Mahono Mahalabaani | The Originators of Gold

Uganda. Busitema Sub County. Mahono Mahalabaani, is the title chosen by the gold mining community, meaning "Struggling Hands". In this personal cinematic portrait the men and women give their accounts of the daily challenges presented...

Uganda. Busitema Sub County. Mahono Mahalabaani, is the title chosen by the gold mining community, meaning "Struggling Hands". In this personal cinematic portrait the men and women give their accounts of the daily challenges presented...